FAQ: How does 3D printing work?

3D printing is the process of creating a physical object by adding material, usually in layers, until a part is built. 3D printing is a type of Additive Manufacturing (AM). The more traditional manufacturing processes such as milling or turning are considered subtractive manufacturing.

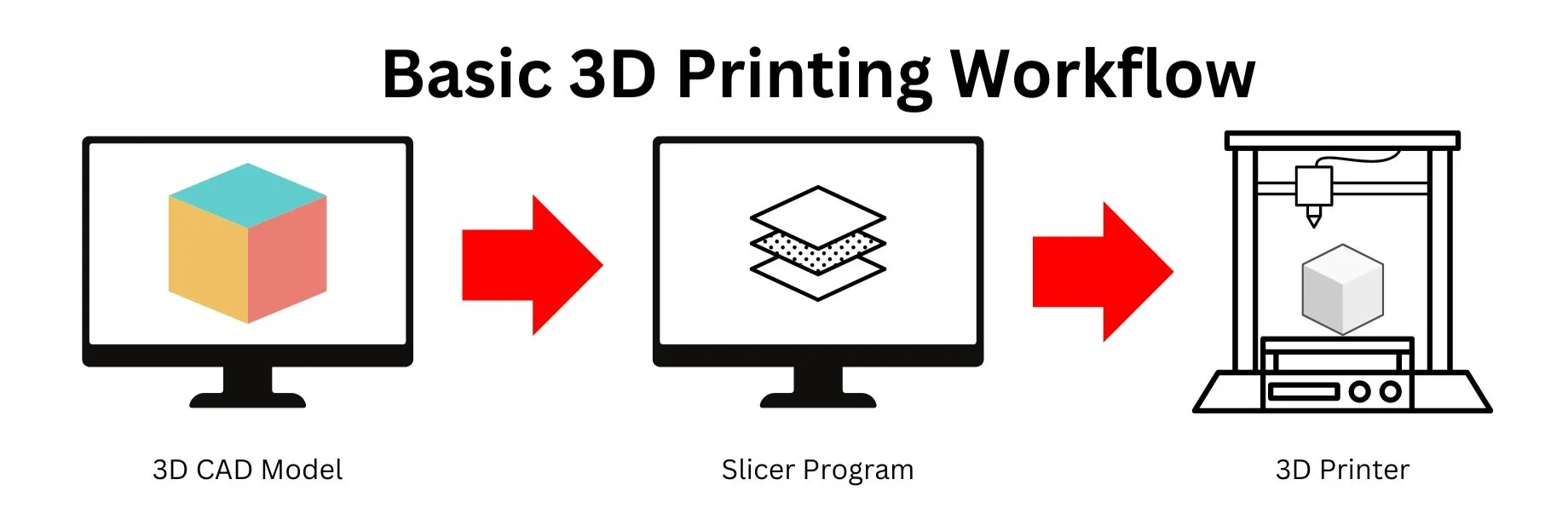

3D printing creates objects based off of 3 dimensional computer data. Typically designed in a Computer Aided Design (CAD) program such as Ashlar-Vellum Xenon, object geometry is captured in a CAD file. All modern CAD softwares export files that can be used for 3D printing.

The 3D CAD file is then run through a slicer program (such as Simplify3D) that "slices" the part into layers for printing and generates the machine code used to make the part. The slicer outputs a print file or build file - “gcode” in the case of GZERO Additive machines.

Once the build file is generated, it is sent to the 3D printer. The 3D printer should be loaded with the appropriate material prior to sending the build file.

Once the print has completed it is removed from the 3D printer. Depending on the part and appearance requirements, post-processing may be necessary. Post-processing may include support structure removal, sanding, filling, painting, vapor smoothing, or installing heat set inserts.

There are many types of 3D printing. The most popular method, which is used by GZERO Additive machines, involves heating thermoplastic material inside of a small nozzle and precisely depositing that material onto a platform layer-by-layer until a part is built. This is the fastest process for building medium to large sized parts. Many different thermoplastics are available for different applications, from low-cost mockup prototypes to high strength end use parts and many more.

This method of depositing thermoplastic from a nozzle has several names: The original, FDM® (Fused Deposition Modeling), was trademarked by Stratasys in 1991. This means that no other company can market FDM® machines without licensing the name. As a result, Fused Filament Fabrication (FFF) has become popular in the 3D printing industry. FFF and FDM® both refer to the exact same process. These processes also fall under the broader umbrella of Material Extrusion (MEX) and Extrusion-based Additive Manufacturing (EAM).